Home>Products>palm kernel oil making machine>Palm kernel oil mill screw press machine for oil mill plant

Palm kernel oil mill screw press machine for oil mill plant

- MJ

palm kernel oil making machine

- Shandong, China (Mainland)

- ISO 9001 ,CE,BV, ISO

- 1 set

- palm kernel oil making machine

- standard package

- contact with us

- T/T,Western Union

- Expeller Pressed Machine

-

Candy Liu2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Candy Liu2020-07-10 09:46:19

Welcome to my shop! Glad to serve you! Please send your question!

Product Description

Customers-- Palm kernel oil mill screw press machine for oil mill plant

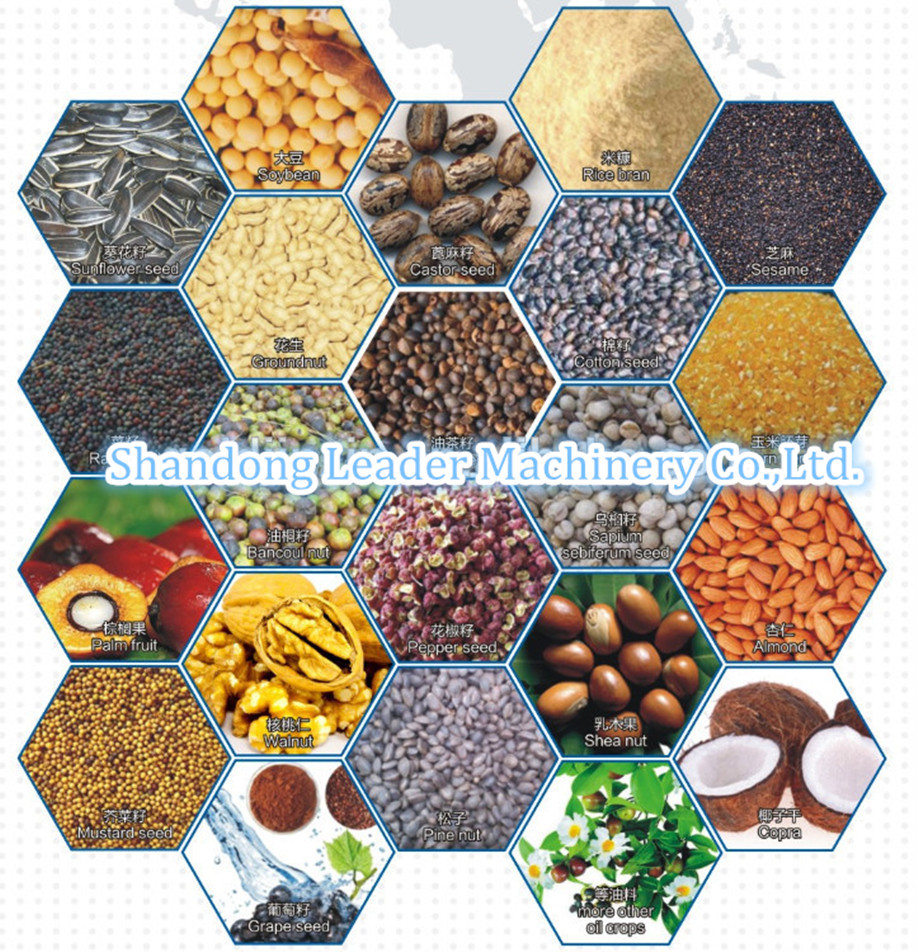

Shandong Leader Machinery Co.,ltd. have customers from all over the world like Uzbekistan, Kyrghizstan, Kazakhstan,and Canada, Chile, Argentina,Ethiopia, india, malaysia, Zambia, Nigeria, Russia , Turkey, Tunisia ,more than 100 countries overseas.

3. Advantage of tea seeds oil making machine

(1) Simple design, small volume and light weight, easy to handle and move.

(2) Easy for operating, low labor intensity and high economical profit.

Palm kernel oil mill screw press machine for oil mill plant

First. Why choose LD and Oil Co.,Ltd. ?

1.> Our company has been set up since 1984, It has been awarded the "The quality-star enterprise of China", we have more than 30-years history in the manufacturing of and oil machinery.

Second. What can we supply to our customers?

1.> 1TPH Palm fresh fruit bunch(FFB) Press project equipment manufacture,installation and Turnkey project;

2.> 2TPH-10TPH Palm fresh fruit bunch(FFB) Press project equipment manufacture,installation and Turnkey project;

3.> 15TPH-30TPH Palm fresh fruit bunch(FFB) Press project equipment manufacture,installation and Turnkey project;

4.> 40TPH-80TPH Palm fresh fruit bunch(FFB) Press project equipment manufacture,installation and Turnkey project;

5.> 5TPD-500TPD Palm oil refinery project production;

6.> 5TPD-500TPD Palm oil fractionation project production;

7.> Equipment spare part supply;

8.> Project design and technology support.

Palm kernel oil mill screw press machine for oil mill plant Introduction

Palm tree grows in Southeast Asia, Africa, south pacific, and some tropical area in South America. It originated in Africa, was introduced to Southeast Asia in the early 19th century. The wild and half wild palm tree in Africa called dura, and the by breeding, develop a kind named tenera with high oil yield and thin shell. From the 60s last century, almost all the Commercialized palm tree is tenera. Palm fruit can be harvested throughout the year.

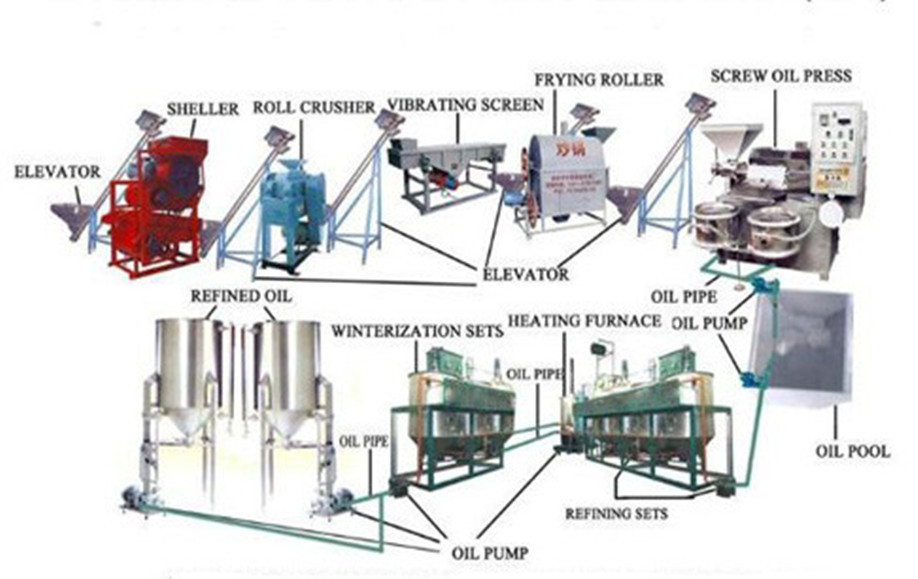

Palm kernel oil mill screw press machine for oil mill plant Process Flow

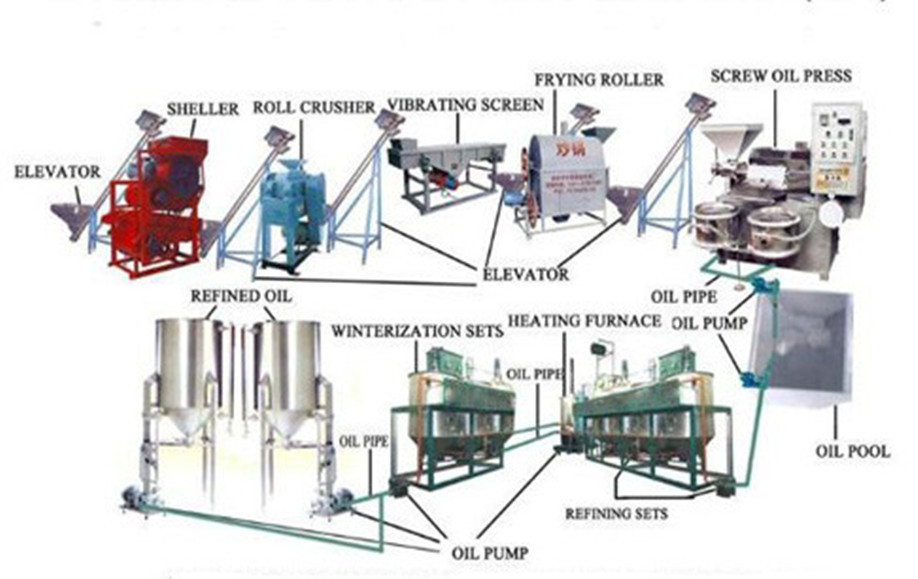

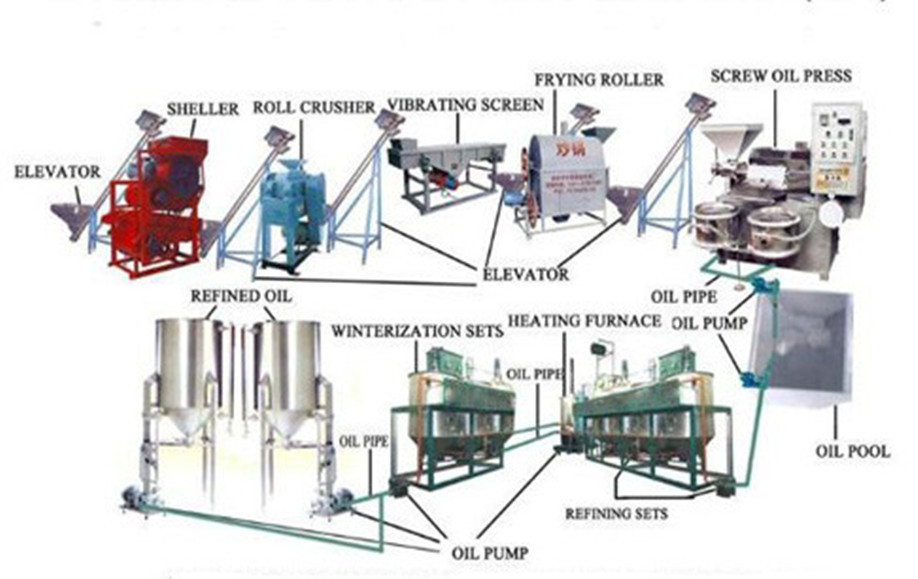

1st. Step Reception station of palm kernel oil expeller

Palm fruit oil mill Reception is used for loading the Fresh fruit bunch (FFB) to the palm fruit cage. Adopt hydraulic control system. as our experience, some palm oil pant use concrete structure, but it’s not good for cleaning. Now we adopt steel material, fence structure. Some impurity will drop down to a conveyor, impurity will conveyed to outside. Easy for cleaning.Fresh palm fruit bunch will be loaded on a slope. Under the slope, there are some cages to receive the palm fruits.

2nd.Step Sterilizer of palm kernel oil expeller

FFB transported by scraper conveyer fall into sterilizing tank, make FFB soft,get more oil yield. sterilizing time 90~120mins, temperature 130~145℃.Sterilizer can be design as owner’s requirement.horizontal sterilizer or vertical sterilizer for our customer.

Fresh palm fruits bunch are airtight sterilized in sterilizer. The purpose to prevent enzymes broken down, avoiding FFA content in oil further increase.

3rd Step Thresher Station of palm kernel oil expeller

Palm fruit thresher in palm oil plant is used for separate empty fruit bunch and palm fruit.

4th Step Oil Press Station of complete line palm kernel oil expeller

Pressing station in palm oil plant is include digestor and oil presser.

Sterilized palm fruit from thresher conveyed to digestor.

5th Step Screening filter of complete line palm kernel oil expeller

Clarification in the palm oil station. For crude oil cleaning, we use screening filter and Decanter Centrifuge to remove the impurity in the crude oil. After process the impurity in the oil can get storage standard

6th Step Decanter Centrifuge of complete line palm kernel oil expeller

Clarification in the palm oil station. For crude oil clean, we use screening filter and Decanter Centrifuge to remove the impurity in the crude oil. After process the impurity in the oil can get storage standard.

Technology Parameter of complete line palm kernel oil expeller

| Oil content in FFB : | ≥24% | Oil extraction rates : | 22~23% |

| Shell content in FFB : | ≥6~7% | Kernel content in FFB: | 6.5% |

| Empty bunch content in FFB: | 23% | Fiber content in FFB : | 12~15% |

| Oil content in empty bunch: | 5 % | Press cake proportion in FFB: | 24 % |

| Solid phase in empty bunch: | 32% | Moisture in empty bunch : | 63 % |

| Water content in press cake : | 40 % | Oil content in press cake: | 6 % |

| Oil content in nut: | 0.08% | Solid phase in press cake : | 54 % |

| Oil content on meter solid: | 3.5% | Oil content in wet meter heavy phase | 1% |

| Fruit in empty bunch: | 0.05% | Oil content in final effluent: | 0.6% |

| Kernel in empty bunches: | 0.05% | Water in palm kernel | ≤7% |

| Kernel content in LTDS: | 0.15% | Kernel content in cyclone fiber: | 0.15% |

| Kernel content in wet shell: | 2.5% | Kernel content in dry shell: | 2% |

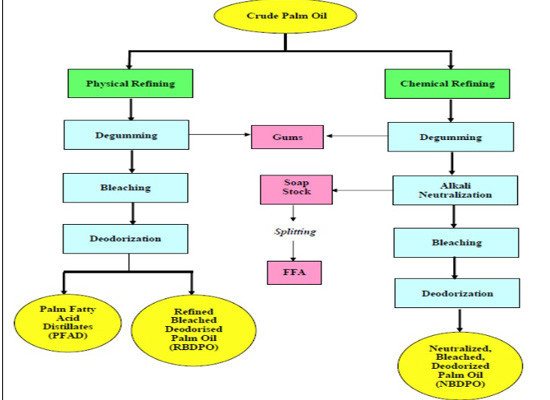

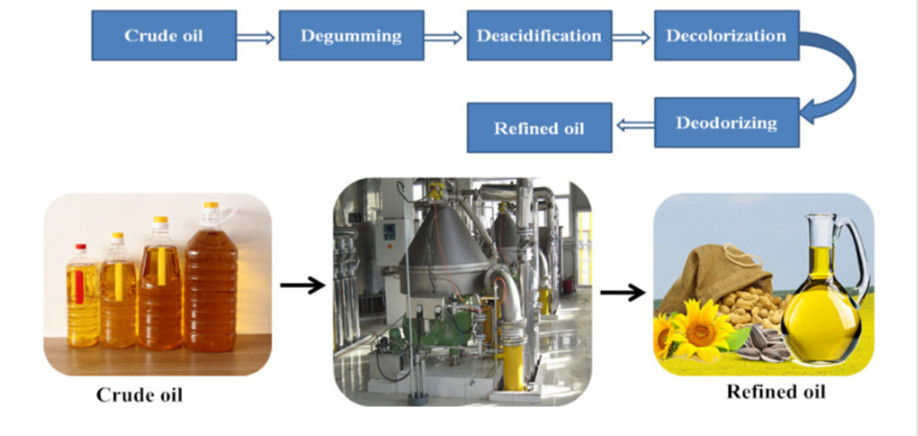

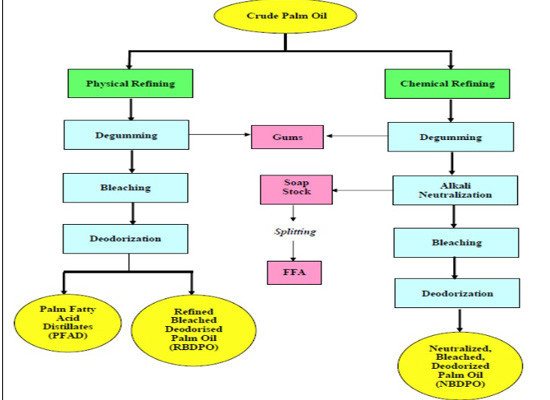

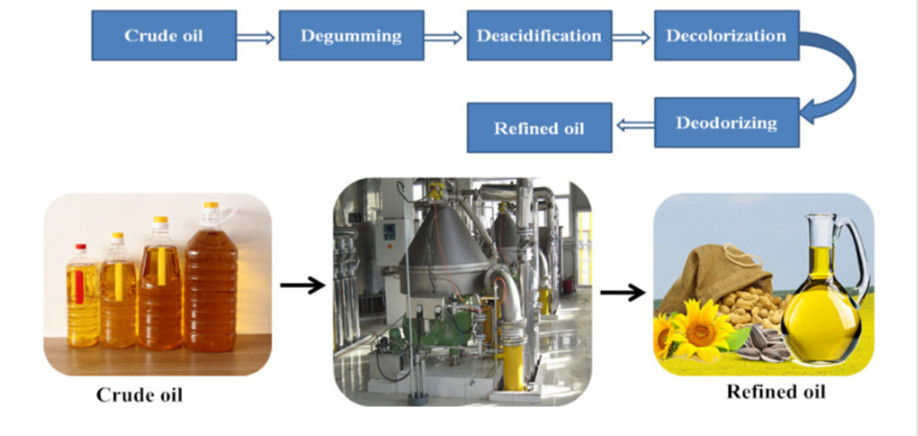

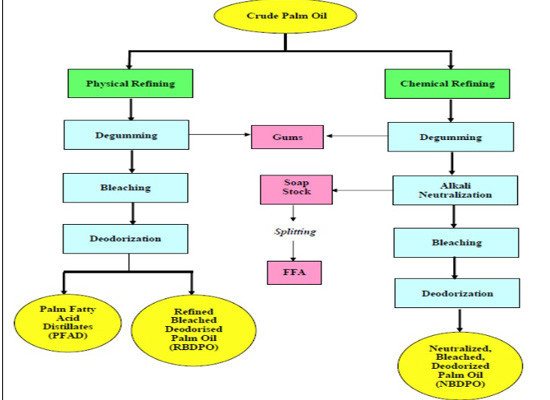

II part. What is the section of palm kernel oil refinery & fractionation ?

1.Degumming of palm kernel oil solvent extractor equipment

This is the most important section of hydrate de-gumming, manage the adding water (there is a little P-acid in the water) amount, temperature and add water speed, usually water adding amount is about 3 times of phospholipid content, that is 3-10% oil weight, water temp needs to be higher than oil temp.

2.Deacidification of palm kernel oil solvent extractor equipment

This part adopt alkali refining method, that is use alkalis like (NaOH) to neutral the free fatty acid in oil, during this process it will produce soapstock , then separated from the oil by setting several hours.

3.Decolorization of palm kernel oil solvent extractor equipment

In normal situation , there is pigment in the crude oil , we need to using the active clay to absorb the pigment away , after 20 mins , we use the vibrating filter to filter the waste clay away . If you want to get light color oil , you need to add more active clay . That is mean , the customer can accord to his requirement to control the oil color. This process is carried out under the vacuum condition.

4.Fractionation of palm kernel oil solvent extractor equipment

Palm oil fractionation and production technology developed by our company is one advanced technology, full computer automatic cooperation, lower investment cost, high liquid oil yield, high solid fat purity and high benefit.

Certifications

Certifications

Detailed Images

Detailed ImagesProject Image 2

Name: Vegetable Oil Refining Plant

Brand: Beiside

Original: China

Domestic famous engines, strong driving force, low fuel consumption, high economic benefits 12F+4R sliding sleeve shift.

Project Image 3

Name: Vegetable Oil Refining Plant

Brand: Beiside

Original: China

Domestic famous engines, strong driving force, low fuel consumption, high economic benefits 12F+4R sliding sleeve shift.

Project Image 4

Name: Vegetable Oil Refining Plant

Brand: Beiside

Original:China

Domestic famous engines, strong driving force, low fuel consumption, high economic benefits 12F+4R sliding sleeve shift.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

| Packaging | |

| Size | 123 (L) * 456 (W) * 789 (D) |

| Weight | 1.2 T |

| Packaging Details |

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request. |

Refinning Plant

91.8% Response Rate

200 Screw Oil Presser with Cooker

91.8% Response Rate

Vibrating Oil Filtering Machine

91.8% Response Rate

Product Description of Palm kernel oil mill screw press machine for oil mill plant :

This series of Palm kernel oil mill screw press machine for oil mill plant are an excellent model of palm oil making machine through numerous experiments and long time usage by all of the world clients.The palm oil making machine has advantage of high efficiency, low consumption, simple operating, stable function, easy to maintain,high productivity and high oil output ratio

AAA1

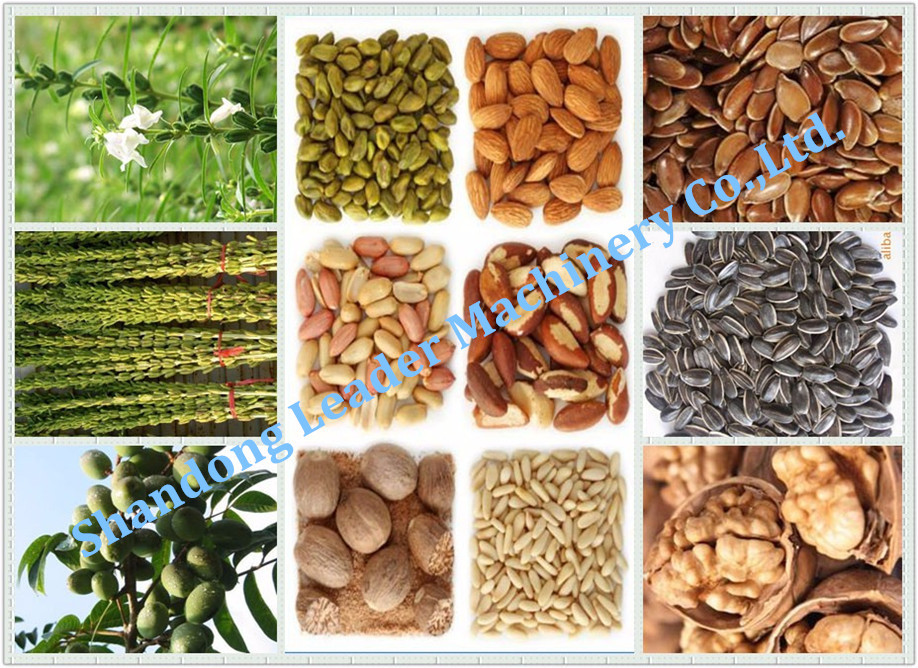

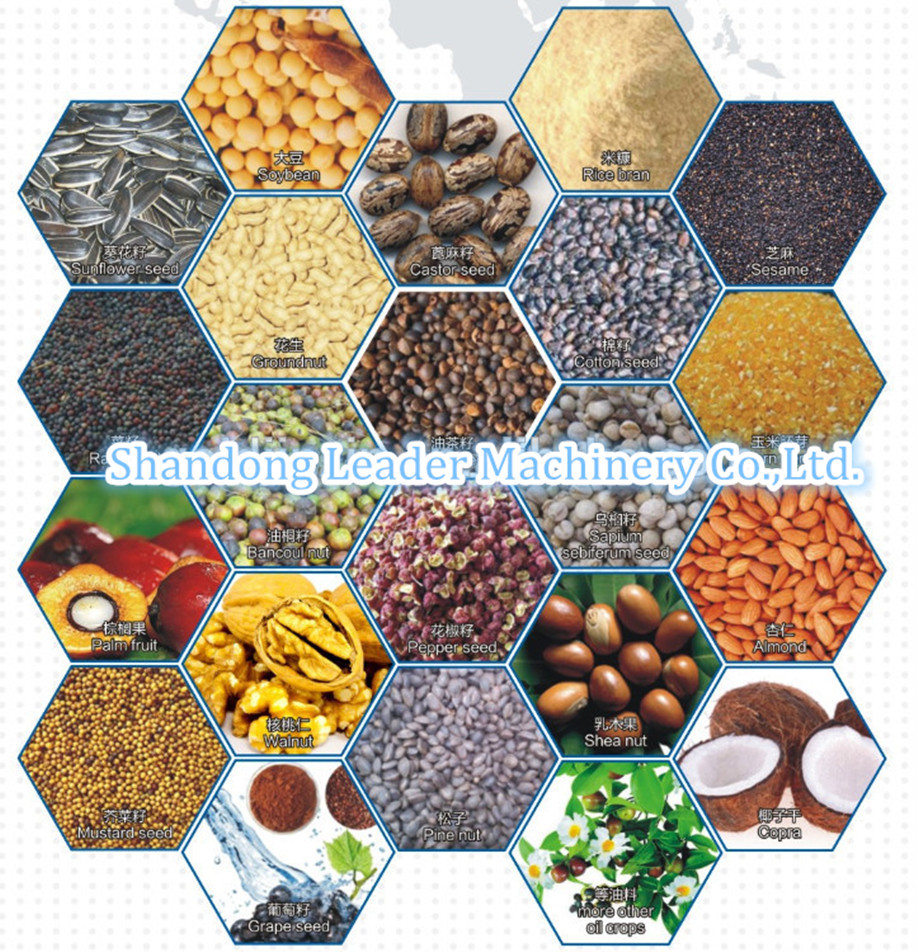

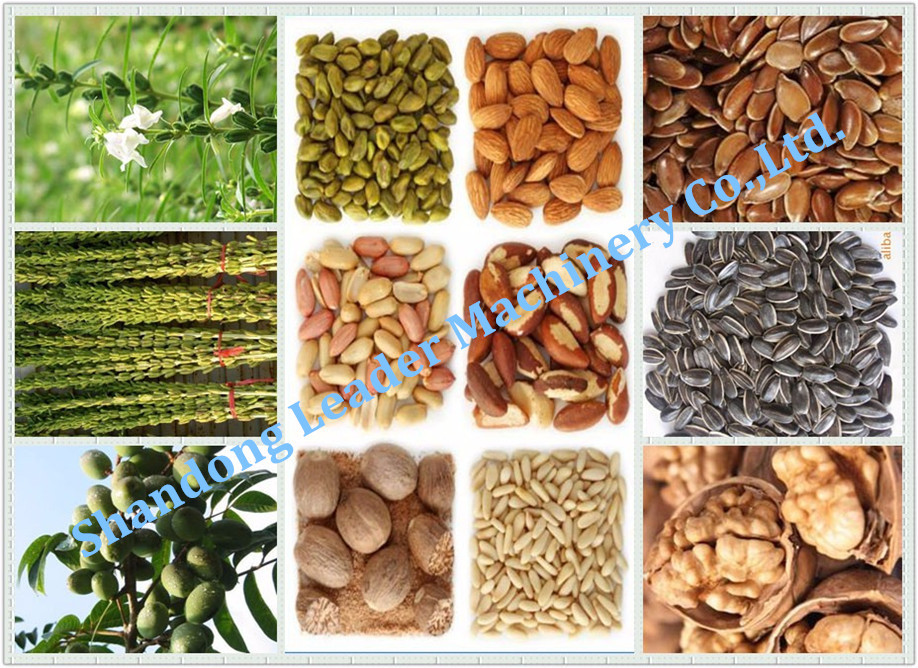

Application of Palm kernel oil mill screw press machine for oil mill plant :

The Palm kernel oil mill screw press machine for oil mill plant is widely used in squeezing oil from vegetable oil seed,such as soybean, peanut, sunflower seed, cotton seed, sesame, tea seed, copra, jatropha curcas, castor seed ,etc. it is specially for the palm fruit better after adjusting its structure

AAA2

Palm kernel oil mill screw press machine for oil mill plant mill used to corn soybean peanut palm coconut rapeseed cooking oil press / making/extracting machine

are advanced oil processing machinery, characterized by their simple design, easy to use,wide suitability and continuous operation; and high productivity and high oil output rate.Moreover,theycan be used for various raw materials, as ground nuts, bean, rice bran,rape and cotton seeds, sesame, olive,sunflower, coconuts and cocoa and grass seeds. However, they are suitable for medium-small sized oil extruding workshops or professional farmers. Certainly, they can be used for repressing in submerging oil workshops, too.

AAA3

If you have any demand about microwave drying equipment and edible oil refining equipment, pls feel free contact us any time.

LD Miss Candy

Skype: leaderfoodmachine9

Mobile: +86 18363700691 (Also WhatsApp & Wechat)

Email: [email protected]

Shandong Leader Machinery Co.,Ltd.

Tel:+86 0531 85064681

Fax:+ 86 0531 85064682

Skype: taishan0072

What’sApp:+86 18905316466

Email: [email protected]

Address: No. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

At Shandong Leader Machinery Co.,Ltd, we have one single goal in mind: to make you a satisfied customer. That single focus, driven from every aspect of the company's operation, is the key to our ongoing success. If you're a satisfied customer, you'll come back to us when you have additional Machine needs in the future, and you'll tell your friends about us. Then if we can make them satisfied customers, the cycle continues.

——————————————————————Wendy Yao Director

Contact Us

- Expeller Pressed Machine

- Email[email protected]

- AddressAddress: No. 225, Huangqiao Village, Beiyuan, Tianqiao District, Jinan, Shandong, China

- Phone(Working Time)Tel:+86 0531 85064681

- WhatsApp+86-18363700691

Related News

| Common faults and troubleshooting of oil hydraulic system |

| Treatment of oily sludge by solvent extraction |

| Application of solvent extraction equipment in uranium hydrometallurgy process in China |

Product Categories

- Microwave Tunnel Thawing machine

- Oil Mill Machinery China Manufacturer

- cold press oil machine

- sunflower oil press machine

- Tea seed oil press machine

- Tea Microwave Dryer Sterilizer

- China supplier microwave drying and roasting equipment

- Solvent Extraction Plant

- Solvent Extraction Line

- 1-20TPD Small Scale Oil Refining Line

- Oil Machine

- Corn Flour Processing Plant

- Chemical Material Drying Sterilization Equipment

- Ready Meal Heating Equipment

- Mustard Oil Mill Manufacturers

- microwave vacuum dehydrator

- Coconut oil Press Machine

- Corn Germ Oil Plant

- Small Scale Screw Pressing Machine

- Rice Bran Oil Plant Processing

- Small Scale crude Oil Refining Machinery

- palm kernel oil making machine

- Oil Fractionation Equipment

- Microwave Crops dryer sterilizer

- Cotton Seed Oil Extraction Machine

- Hydraulic Oil Press and Home Oil Press Manufacturer

- Solvent Extraction Method for Edible Oil Processing

- Canola/Rapeseed Oil Plant

- Palm Oil Processing Machine

- Sunflower Seed Oil Plant Equipment

- industrial sized microwave

- cooking oil machine for sale

- industrial microwave convection oven

- Edible Oil Filling Line

- Microwave Drying Equipment

- Auxiliary Machine For Oil Press

- Shea Butter Oil Plant

- Oil Milling Machine

- coconut oil machine

- Vegetable Oil Refining Machine

- Sea food dryer sterilizer

- Microwave Sterilization Equipment

- Mini Crude Oil Refinery Plant

- Oilseeds Processing Line

- Oil Refining Machine

- Main Processes of Manufacturing Rice Bran Oil

- Groundnut Oil Plant Equipment

- Rice bran Oil Extraction Machine

- Sesame Seeds Roasting Machine

- Oilseeds Pretreatment Equipment

- Walnut Edible oil production line

- soybean oil plant in maharashtra

- Biodiesel Oil Production Line

- Wheat Flour Processing Plant

- Full Continuous Refining Line

- herbs drying sterilizing equipment

- Seed Hydraulic Press Machine

- Palm Fruit Processing Line

- almond oil plant machine

- Spices Microwave Dryer Sterilizer

- Sunflower Oil Plant

- Palm Fruit Processing Line

- Peanut/groundnut oil mill plant

- Large Scale Screw Pressing Machine

- Sesame/Niger Seed Oil Plant

- Screw/Hydraulic Oil Press

- Cooking Oil Production Line

- Castor Oil Extraction Machine

- Nut Microwave Roasting Machine

- Screw Type Oil Press

- Coconut Oil Plant Equipment

- Shea Butter Oil Plant Equipment

- Coconut/Copra Oil Plant

- soy protein production line

- Auxiliary Machine For Oil Press

- Continous Single Layer Mesh Belt Dryer Conveyor Dryer

- Hot air drying oven

- Fruit and vegetable drying machine

- Herb drying machine

- Micro Wave Oven

- fastfood microwave fast heating equipment

- Multi-layer Oven

- Incense drying machine

- Microwave dryer for chemicals

- microwave vacuum drying equipment

- Microwave dryer for food

- Hot air dryer

- sludge dryer machine

- Vegetable Drying Machine

- freeze dryer machine

- Microwave dryer for laboratory use

- Microwave drying sterilizer machine

- Microwave Heating Thawing Machine

- Microwave Pyrolysis and Extraction equipment

- Bread Crouton chips line

- Sweet potato starch machine

- twin screw extruder

- Stretch Film Machine Rolls

- Starch modified machine

- floating fish feed extruder machine

- Artificial rice extrusion line

- Frying Instant Noodles machine

- Japanese Peanut Equipment

- starch machine

- Nutritional Powder extrusion line

- Microwave drying machine

- TOFU PRODUCTION LINE

- Single screw extruder

- Pop cereals grains machine

- snack pellet production line

- Potato chips production line

- Chocolate Bar Machine

- 123

- Spaghetti Straws Making Machine

- Biodegradable Drinking Straws Making Machine

- weighing packing machine

- automatic weighing and packaging machine

- auto bagging weighing machine

- industrial belt dryer

- continuous tunnel dryer

- hot air drying tunnel

- commercial potato chip maker

- potato chip slicer machine

- bread production line

- fish food processing line

New Products

Automatic electric palm kernel oil processing machine/palm oil production line

Automatic electric palm kernel oil processing machine/palm oil production line 100TPD Crude Palm Kernel Oil Production Line/Palm Kernel Oil Pressing Machine/Palm Kernel Oil Refinery Machine

100TPD Crude Palm Kernel Oil Production Line/Palm Kernel Oil Pressing Machine/Palm Kernel Oil Refinery Machine Palm oil processing machine,Palm oil production line, Crude Palm oil refinery and fractionation plant turn-key project

Palm oil processing machine,Palm oil production line, Crude Palm oil refinery and fractionation plant turn-key project Palm oil filter production line

Palm oil filter production line Chinese palm fresh oil processing machinery manufacturer for edible oil mill

Chinese palm fresh oil processing machinery manufacturer for edible oil mill

Oil Mill Machinery China Manufacturer cold press oil machine soy protein production line Auxiliary Machine For Oil Press Continous Single Layer Mesh Belt Dryer Conveyor Dryer Hot air drying oven Fruit and vegetable drying machine Micro Wave Oven fastfood microwave fast heating equipment Multi-layer Oven Bread Crouton chips line Sweet potato starch machine twin screw extruder Stretch Film Machine Rolls Starch modified machine floating fish feed extruder machine Artificial rice extrusion line Frying Instant Noodles machine Japanese Peanut Equipment starch machine Nutritional Powder extrusion line Microwave drying machine TOFU PRODUCTION LINE Single screw extruder Pop cereals grains machine snack pellet production line Potato chips production line Chocolate Bar Machine 123